Beyond softwood: towards circular pathways for the timber industry

Today, the European timber construction industry relies almost entirely on softwood from large production forests. Alternative wood sources, such as hardwood from urban forests, damaged trees, and post-consumer wood are rarely used. This lack of diversity has helped the industry scale up through standardised manufacturing processes. Yet, these same processes also create vulnerabilities: they limit the inclusion of more irregular wood, increase pressure on softwood forests, and slow the shift to a circular bioeconomy. To build a more sustainable future, these processes need to be adapted.

Historically, Europe has often made creative use of local and irregular wood. Viking ships were shaped around the natural curves of trees, and Dutch windmills still showcase a mix of locally sourced hardwood species. Over time, industrialisation and standardisation of timber have improved efficiency but reduced flexibility towards more diverse or irregular wood stocks.

How can we bring back more diverse and irregular wood into design and construction processes? WoodStock explores alternative design approaches and new technologies, giving the industry the opportunity to rediscover this flexibility.

Approaches

Current best practices show two main categories of approaches in designing with irregular wood:

1. Embracing the irregularity of the wood by tailoring products and buildings to the unique shapes and properties of wood.

2. Standardising through processing by transforming irregular stocks into uniform products.

Both approaches start by mapping the available wood stock.

Process steps

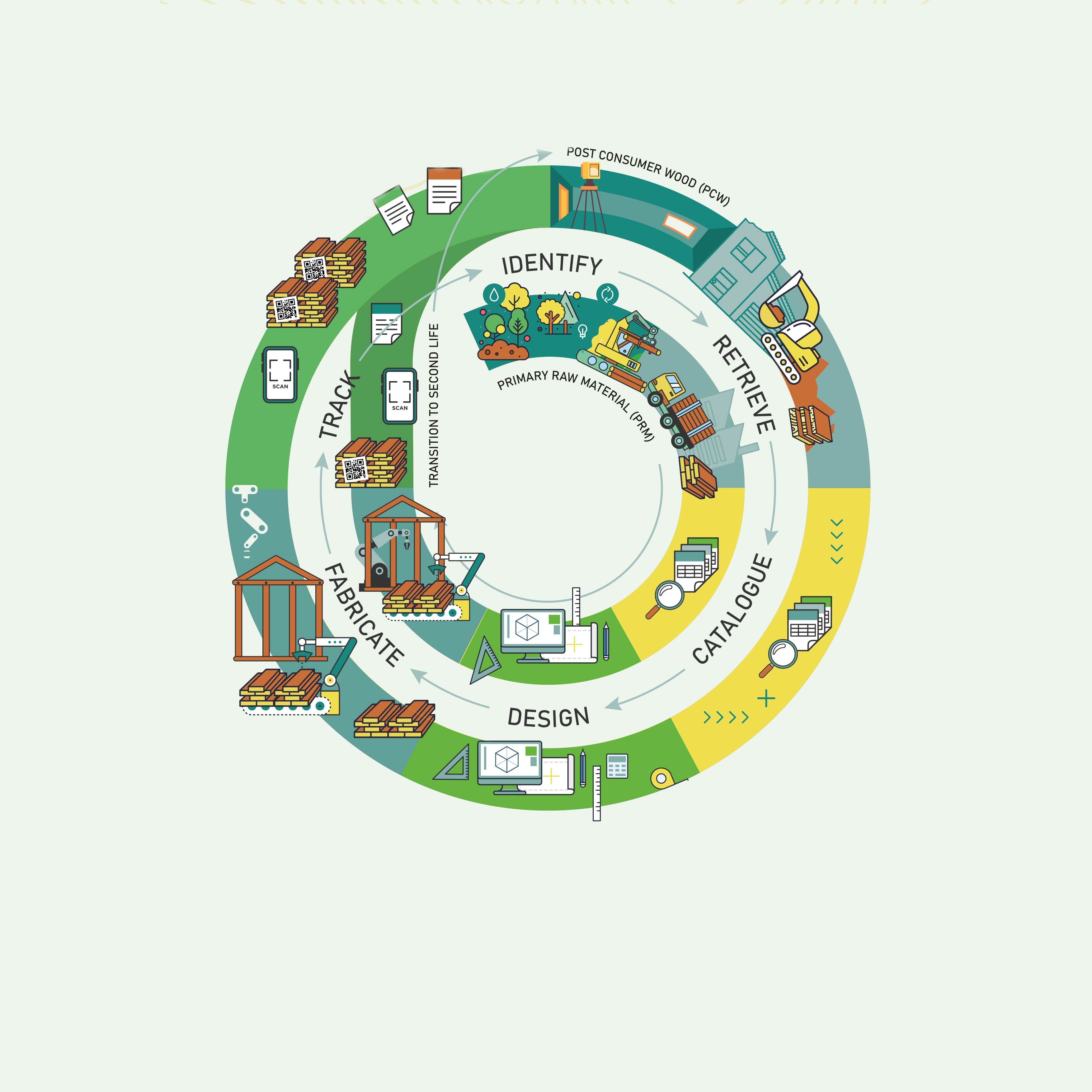

In a closed-loop process, this involves six phases:

1. Identify potential sources

2. Retrieve or collect the material

3. Catalogue properties using artificial intelligence and computational tools

4. Design products and structures by using data-driven methods

5. Fabricate with automated processes, including robotics

6. Track relevant data during different use cycles for future reuse of wood

By combining tradition with technology, Europe’s timber industry can move beyond softwood dependency and unlock the potential of diverse, irregular wood — creating a more circular and resilient future.